Description

Internal Roller Burnishing Tools for Through Hole

ID Through Roller Burnishing Tools produce fine surface finishes and control size in ID surfaces. The tools are easy to set for diameter with the micrometer adjustment nut.

Roller burnishing is a chipless machining method which cold works the metal without cutting or abrading the surface. It removes no metal but rather compresses, or “irons out”, the peaks of a metal surface into the valleys, generating a dense and uniform surface.

Inside Diameters Through Hole Roller Burnishing Tool, ID Through Hole Roller Burnishing Tool RBT-IDT Supplier

Features & Benefits:

Accurate sizing

Fast cycle time

Eliminate secondary operations

Metallurgical improvements:

Work hardening

Resistant to fatigue failure

Corrosion resistance

Specifications:

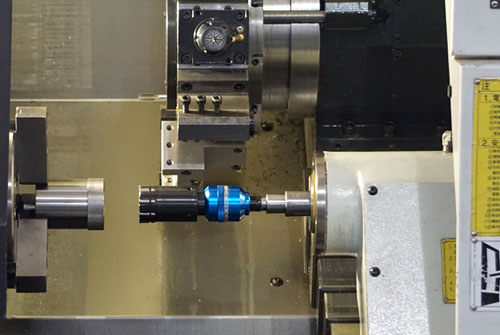

Can be run on almost any machine tool either the tool or work piece can rotate.

Flood coolant is required.

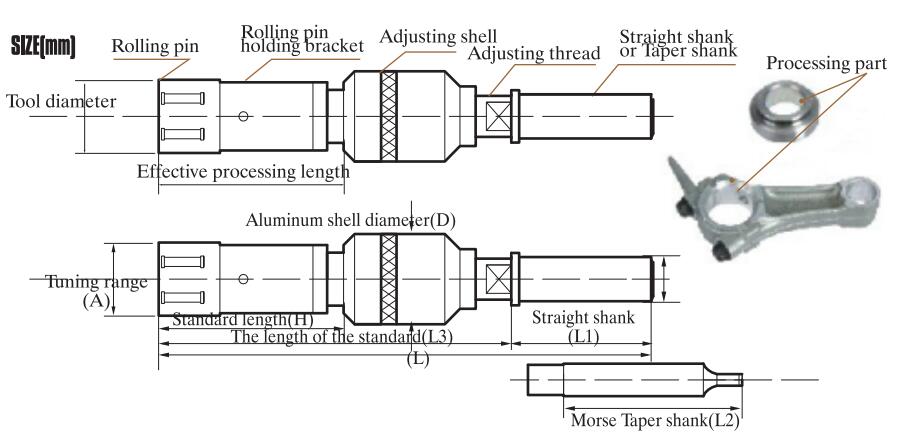

ID Through Roller Burnishing Tool Size

ID Through Roller Burnishing Tool Specifications

Straight shank (L1) |

Type*Length | Morse Taper shank (L2) |

Type*Length | Tool Length | |

|---|---|---|---|---|---|

| φ12*32 | 2#*78.5 | Straight shank L1+L3 |

Morse shank L2+L3 |

||

| φ16*32 | 3#*98 | ||||

| φ20*50 | 4#*123 | ||||

| φ25*50 | 5#*155.5 | ||||

| φ32*50 | 6#*217.5 | ||||

| φ40*50 | |||||

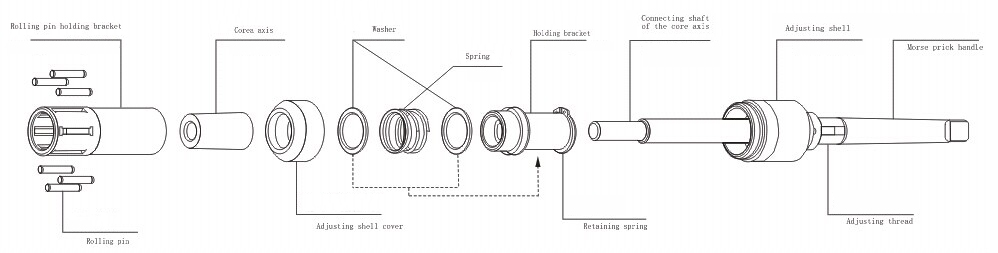

Roller Burnishing Tools Parts

ID Through Roller Burnishing Tool Application

| Driving units |

|---|

| Drilling machine |

| Drilling unit |

| Lathe |

| Machine center |

| Pillar drill (Bench drill) |

Reviews

There are no reviews yet.