Description

Specifications of Deburring Tools

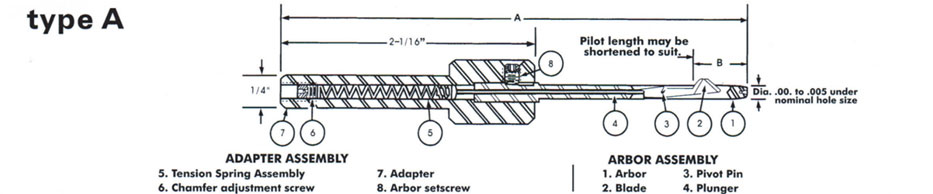

RBT ultra deburring tool type A drawing

| Tool Model | HOLE SIZES | Dim.(A) |

Dim.(B) |

BALDE SIZE | ROTATE SPEED(RPM) |

|---|---|---|---|---|---|

| RBT-FT-3 | 3 | 87.5 | 3.5 | sv-1/8# | 800-1000 |

| RBT-FT-4 | 4 | 98 | 3.5 | sv-1/8# | 800-1000 |

| RBT-FT-5 | 5 | 105 | 3.8 | sv-3/16# | 800-1000 |

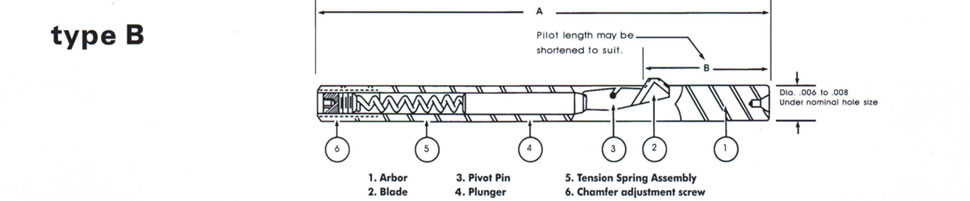

RBT ultra deburring tool type B drawing

| Tool Model | HOLE SIZES | Dim.(A) |

Dim.(B) |

BALDE SIZE | ROTATE SPEED(RPM) |

|---|---|---|---|---|---|

| RBT-FT-6 | 6 | 110 | 5 | 1# | 800-1000 |

| RBT-FT-7 | 7 | 110 | 5 | 1# | 800-1000 |

| RBT-FT-8 | 8 | 115 | 5 | 2# | 800-1000 |

| RBT-FT-9 | 9 | 127 | 5 | 3# | 800-1000 |

| RBT-FT-10 | 10 | 127 | 5 | 3# | 800-1000 |

| RBT-FT-11 | 11 | 127 | 5 | 3-1/2# | 600 |

| RBT-FT-12 | 12 | 127 | 5 | 3-1/2# | 600 |

| RBT-FT-13 | 13 | 127 | 10 | 3-1/2# | 600 |

| RBT-FT-14 | 14 | 140 | 10 | 4# | 600 |

| RBT-FT-15 | 15 | 140 | 10 | 4# | 600 |

| RBT-FT-16 | 16 | 155 | 10 | 4# | 600 |

| RBT-FT-17 | 17 | 155 | 10 | 4# | 600 |

| RBT-FT-18 | 18 | 155 | 10 | 4# | 600 |

| RBT-FT-19 | 19 | 180 | 10 | 4# | 600 |

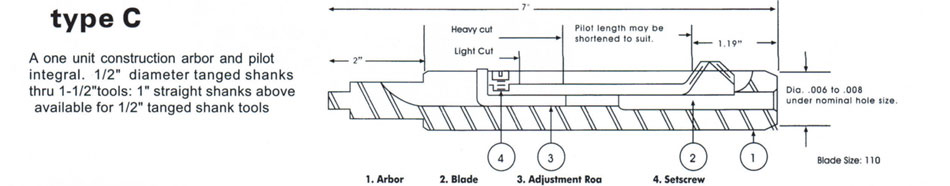

RBT ultra deburring tool type C drawing

| Tool Model | HOLE SIZES | BALDE SIZE | ROTATE SPEED(RPM) |

|---|---|---|---|

| RBT-FT-20 | 20 | 5# | 600 |

| RBT-FT-21 | 21 | 5# | 600 |

| RBT-FT-22 | 22 | 5# | 600 |

| RBT-FT-23 | 23 | 5# | 600 |

| RBT-FT-24 | 24 | 5# | 600 |

| RBT-FT-25 | 25 | 5# | 600 |

Micro Deburring Tools

Features:

HOW RBT UNIVERSAL DEBURRING TOOLS WORKS?

How RBT universal deburring tools works?

1. Feed-in

Upon entry, the burr on the front side is removed due to the spring tension holds the cutting blade in the extended position.

2. Feed-thru

As the feeding increase, passing through the bore the blade is pressed under spring pressure and retracted automatically. (The crowned and polished top surface of the cutting edge will not mar inside bore surface of workpiece).

3. Feed-out

Through back side of the hole, spring tension again causes the blade to extend as it emerges from the internal of the workpiece. On the return stroke, the burr is deburred on the back side of hole.

3 types of tools for different bore diameters.

Reviews

There are no reviews yet.