Description

Product Parameters

| Skiving Section | Diameter | Roller Burnishing Section | |||

|---|---|---|---|---|---|

| Speed: (v)m/min | Feed: (s)mm/rev | Max Machining Margin:mm | φmm | Speed: (v)m/min | Feed: (s)mm/rev |

| 80-300 | 1-4 | 0.6 | 38-56.9 | 500-1200 | 1.2 |

| 1 | 57-90.9 | 300-1000 | 1.3-2.1 | ||

| 1-5 | 1.6 | 91-148.9 | 100-800 | 2.2-3.0 | |

| 149-305.9 | 3.7-7.0 | ||||

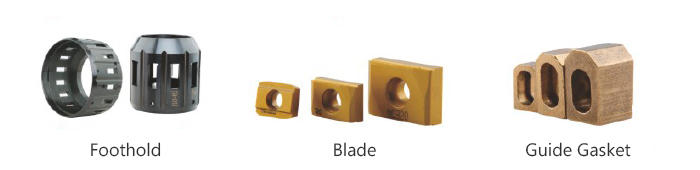

Skiving and Roller burnishing Tools Replaceable Parts

Fitting Parameters

| Skive Roller TGA-*** | Skiving Section TGA-T*** | φD/φG | 38-56 | 57-67 | 68-90 | 91-149 | 150-200 |

|---|---|---|---|---|---|---|---|

| Blade | R420.37-06 | R420.37-07 | R420.37-11 | ||||

| Copper Guide Rod | 300TDX | 400TDX | 38-56 | ||||

| Pin | 300DXT | 400XDXT | 400DXT | 500XDXT | 500DXT | ||

| Cutter Body | TGA-xxxDT | ||||||

| Roller Burnishing Section TGA-G*** | Taper Sleeve | TGA-xxxZT | |||||

| Foothold | TGA-xxxZJ | ||||||

| Connecting Sleeve | TGA-xxxLJT | ||||||

| Needle Roller | 0625/0725GZ | 0830GZ | 1030GZ | 1435GZ | |||

Skive Roller: Cutting and roller burnishing for inner surfaces

The Skive Roller is a multifunction tool that allows you to perform skiving (inner surface cutting within a tube ) and roller burnishing processing continuously. These tools are used for internal finishing of cylinder tubes. During the process, you get rid of irregularities in roundness and straightness, that can occur during the manufacturing of these tubes. Furthermore, the tool will produce the required diameter and will provide an optimal surface through the burnishing operation.

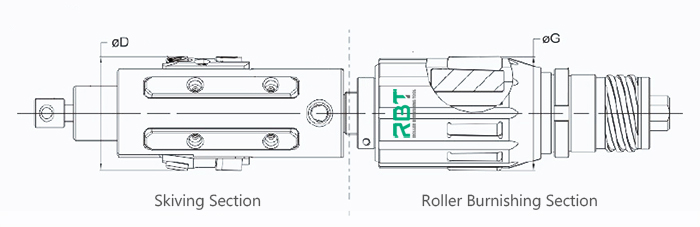

Tool structure

The inner cutting and roller burnishing skive roller is a tool that allows you to perform skiving and roller burnishing simultaneously. To achieve an optimal surface, the tools are equipped with a rough skiving stage and a finishing stage. All RBT skiving and roller burnishing tools will also have a drilling stage, which is used for processing hot rolled tubes that require a large amount of chip removal.

Processing Method

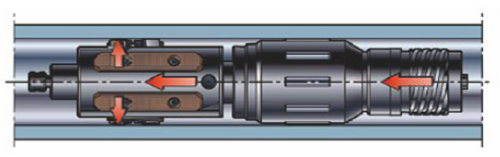

1-way method

Skiving and roller burnishing is performed in the forward direction, the workpiece is quickly returned, and processing is completed.

With this method, because skiving and roller burnishing take place under the same process and quick return is possible, the processing time can be shortened. The processing conditions must be set to either the skiving or roller burnishing conditions.

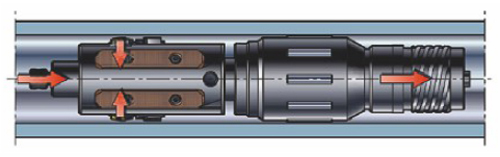

2-way method

Skiving is performed in the forward direction, roller burnishing is performed in the return direction, and processing is completed.

With this method, because the skiving and roller burnishing processes are separate, processing can be performed using the optimal processing conditions for each. However, quick return is not possible.

Becase skive roller is equipped with a burnishing stage that will produce the required surface quality after the drilling and skiving operation. It is perfectly suited for finishing of the inner surface of hydraulic cylinders for construction machinery. The final finish of the inner surface processing of hydraulic and pneumatic cylinders is achieved through honing or grinding.

Reviews

There are no reviews yet.